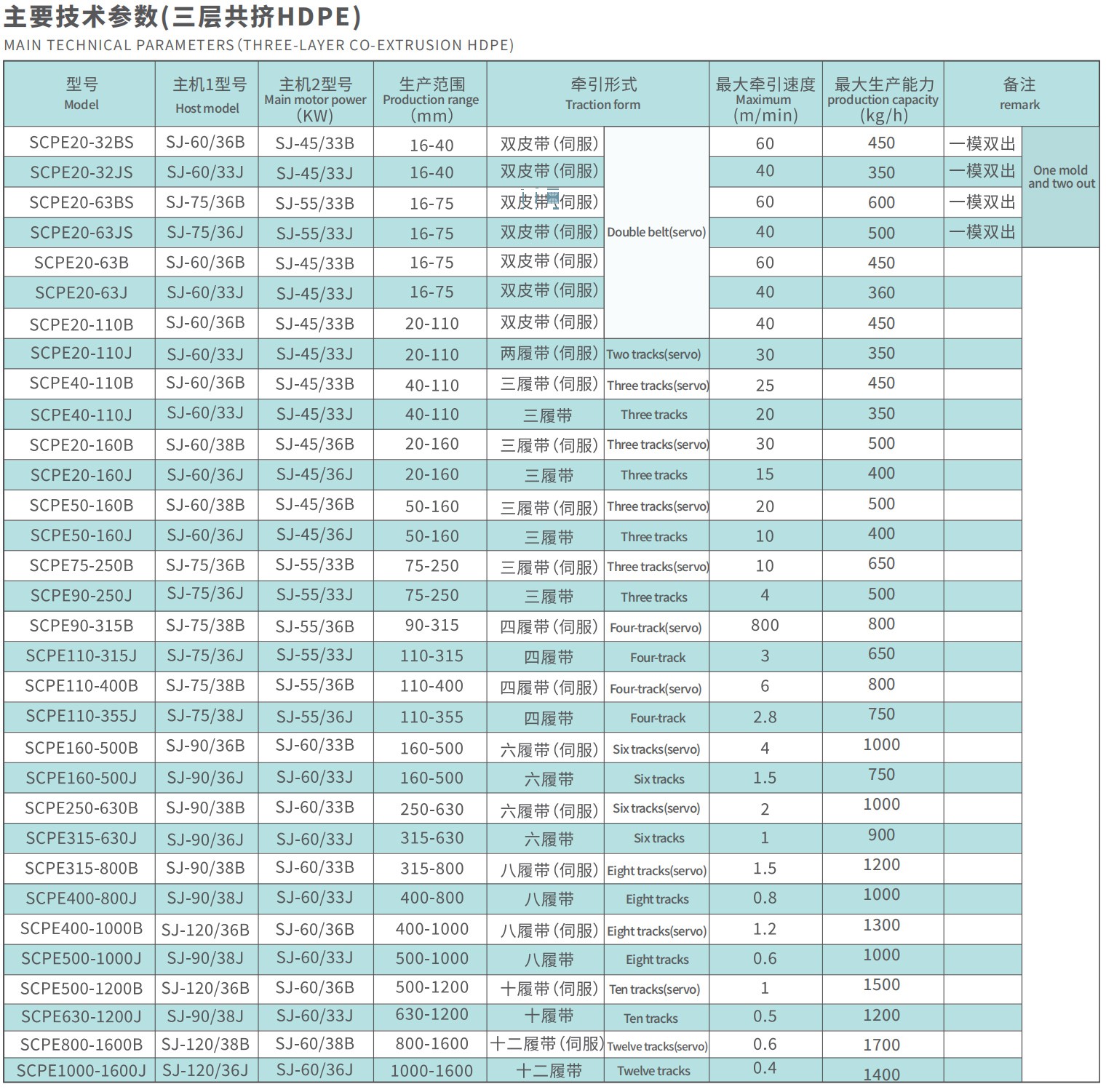

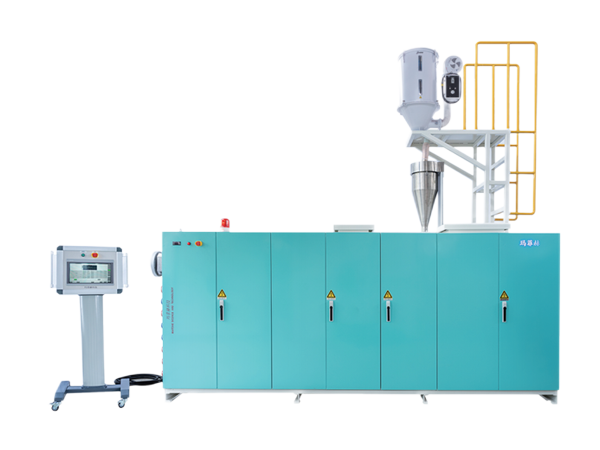

Three-layer coextruded (A+B+A) or multi-layer polyethylene pipe high-speed energy-saving production line

This series of production line through the adjustment of some units, can produce the above series of varieties of pipe, this series of equipment has a beautiful appearance, extremely high capacity cost performance, compared with traditional equipment higher capacity, lower ton energy consumption, more sophisticated high-quality extrusion quality, is the best choice to replace imported brand equipment.

Three-layer coextruded (A+B+A) or multi-layer polyethylene pipe high-speed energy-saving production line

This series of production line is mainly used for the production of polyethylene water pipe (GB/T13663-2018), gas pipe (GB/T15558-2003), polypropylene hot and cold water pipe (GB/T18742.2-2002) heat-resistant polyethylene hot and cold water pipe (GB/T28799.2-2012), polybutene hot and cold water pipe (GB/T19473.2-2004), PP water supply pipe (QB/T1929-1993), high-density polyethylene silicon core pipe (GB/T24456-2009), modified polypropylene power casing (DL/T802.7-2010), this series of production line by adjusting some units, Can produce the above series of varieties of pipe, this series of equipment has a beautiful appearance, extremely high capacity cost performance, compared with traditional equipment higher capacity, lower ton energy consumption, more sophisticated high-quality extrusion quality, is the best choice to replace imported brand equipment.

This series of equipment has the following characteristics:

1, the use of advanced digital bus control mode, all units are using ETHERCAT or CANOPAN interface, CNC bus control can achieve meter weight, extruder, tractor and other digital closed-loop control, than the traditional analog control accuracy of up to 10 times. It can realize the precision control of pipe mining weight when the production capacity is increased, and can also realize the interconnection of the Internet of Things;

2, using the European imported brand of high torque reducer + imported brand coupling + permanent magnet servo motor composed of stable power transmission system, and then equipped with 36/38 aspect ratio of double alloy screw machine simple, can achieve the perfect combination of homogenized melt plasticized melt, low energy consumption ton capacity, high life and high output;

3, optimized design of high-speed mold and sizing sleeve, can achieve high-speed production while meeting high quality products;

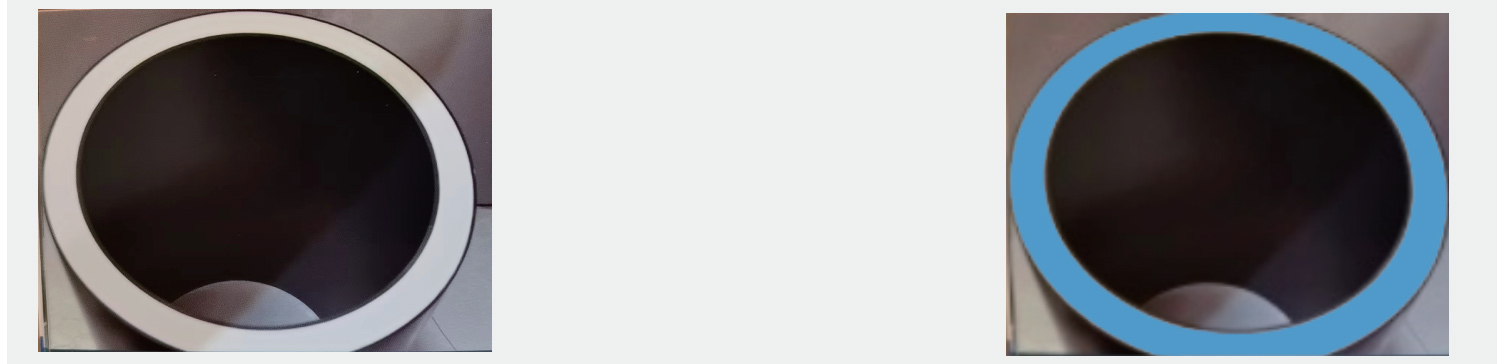

4, unique thermal drainage vacuum box design (Maffei patented products), perfect solution to efficient cooling, greatly improve the cooling efficiency of the pipe surface;

5, high precision servo control tractor, can meet the low speed stability of large caliber, but also meet the high speed accuracy of small caliber, and equipped with ETHERCAT interface, and the main PLC digital closed-loop control;

6, small diameter pipe is equipped with automatic coiling machine, automatic packaging, and equipped with ETHERCAT interface, and the main PLC digital closed-loop control, automatic and traction speed perfect match.